Unmatched Durability and Lightweight Strength

Aluminum tonneau covers combine rugged protection with weight efficiency, offering truck owners durability that outperforms traditional materials. This dual advantage stems from aluminum’s unique material properties, which balance strength and practicality in demanding environments.

Aluminum construction enhances structural integrity and impact resistance

The crystalline structure of aluminum alloys provides a superior strength-to-weight ratio, enabling covers to withstand 300% more impact force than plastic alternatives while remaining 40% lighter than steel. Material scientists attribute this performance to aluminum’s natural energy-absorption capabilities, which reduce permanent deformation from heavy cargo loads.

Comparison with plastic and fiberglass: Why aluminum outperforms

Plastic tonneau covers crack under 250 lbs of downward pressure in cold temperatures, while fiberglass develops stress cracks after 18 months of UV exposure. Aluminum maintains structural stability across these conditions, showing zero warpage in humidity tests and 90% less surface degradation than composite materials over five years.

Resistance to cracking, warping, and extreme weather conditions

Aluminum’s thermal conductivity prevents the heat buildup that warps plastic covers in direct sunlight, maintaining precise fit between -40°F and 150°F. Salt spray resistance testing (ASTM B117) shows aluminum tonneau covers retain 98% of their original integrity after 1,000 hours—crucial for vehicles exposed to winter road conditions.

Improved Fuel Efficiency Through Aerodynamic Design

How Reduced Weight and Drag Contribute to Better Fuel Economy

Aluminum tonneau covers help save gas because they tackle two big issues for trucks: their weight and how they cut through the air. These covers are about 40 to 60 percent lighter than steel ones, so the whole truck isn't as heavy when moving around. That means the engine doesn't have to work quite so hard when speeding up. Plus, the hard shell of aluminum covers creates a smoother surface over the truck bed. This helps reduce those annoying wind pockets that form behind the truck, which actually costs extra fuel as the vehicle fights against itself while driving down the highway.

Aerodynamic Benefits of Hard Aluminum Tonneau Covers

Hard aluminum designs outperform soft covers by maintaining a fixed, streamlined shape that guides airflow over the truck bed. This eliminates the drag-inducing vortex effect common in open-bed configurations. Field tests show tonneau installations reduce aerodynamic drag by 8–12%, translating to measurable fuel savings during highway driving.

Real-World Fuel Savings: Case Study with Aluminum Cover Usage

A 2025 industry study observed 6–7% better fuel efficiency in trucks using aluminum tonneau covers during mixed driving cycles. For a vehicle averaging 18 MPG, this equates to annual savings of $220–$300 (assuming 15,000 miles/year and $3.50/gallon fuel). The aerospace-inspired design principles behind modern aluminum covers amplify these savings at speeds above 55 MPH.

Superior Security and All-Weather Cargo Protection

Advanced Sealing Technology Prevents Water, Snow, and Dust Intrusion

The aluminum tonneau covers feature layered sealing technology that keeps water out of truck beds effectively. The covers have these special EPDM rubber seals along with built-in drains which work together pretty well in real world conditions. Field tests show they block about 98% of water getting through, way better than those cheap vinyl or plastic alternatives that tend to break down after some time on the road. When installed properly, these seals really grip onto the sides of the truck bed, stopping rainwater and melting snow from seeping inside. What makes them stand out is the dual action seal at the tailgate area too many other products miss completely. This extra layer stops all sorts of dirt and grime from building up inside the cargo space, something every truck owner knows can be a real pain to clean later on.

Locking Mechanisms and Tamper-Resistant Design for Theft Prevention

Aluminum has real strength when it comes to supporting security features such as those rotary deadbolt locks and slam latch systems we all want in our trailers. Think about it this way: while soft vinyl covers get sliced open by anyone with a knife, aluminum panels stand their ground unless someone brings out serious industrial equipment to break through them. A lot of these aluminum models actually work right alongside the factory installed tailgate locks, making everything lock up together nicely and giving would-be thieves something to think twice about before trying anything. And let's not forget about those tamper resistant bolts plus the reinforced sides that stop people from prying things apart with bars. These aren't just fancy features either. The FBI reports around 1.1 billion dollars worth of stolen cargo happens every year across North America alone, so having good protection isn't just smart, it's practically essential.

Proven Performance in Rain, Snow, UV Exposure, and Off-Road Conditions

Independent tests have found that aluminum tonneau covers keep working properly across extreme temperatures ranging from minus 40 degrees Fahrenheit all the way up to 160 degrees Fahrenheit (which is about -40 Celsius to 71 Celsius). They don't warp or let seals break down even in these conditions. The powder coating on these covers bounces back around 89 percent of harmful UV rays, so whatever's inside stays protected from sun damage. And when winter comes around, those special ice resistant surfaces actually get rid of snow much quicker than regular textured ones do, clearing off about 40% faster according to test results. For people who love going off road, there's another big plus: during simulated off road driving over 500 miles of rough gravel roads, not a single drop of water got inside the truck bed. Plastic covers typically start leaking long before reaching just 100 miles under similar conditions.

Enhanced Aesthetic Appeal and Increased Resale Value

Sleek, Customizable Finishes That Elevate Truck Appearance

Aluminum tonneau covers today offer both solid construction and those fancy car-like finishes that actually hold up against sun damage without losing color. Plastic ones tend to turn yellow after a few years outside, but the anodized aluminum stuff keeps looking good because it reflects around 95% of UV rays, as noted in last year's industry report on vehicle coatings. Most folks want some control over how their truck looks, so manufacturers now offer different finish options like matte, satin, or glossy sheen. A recent survey found that nearly two thirds of people buying these truck bed covers see this kind of customization as pretty much mandatory when shopping for accessories.

How an Aluminum Tonneau Cover Boosts Resale Value

When it comes to keeping truck values high, durability and looks really matter. According to the latest market research from 2024, trucks with aluminum bed covers hold about 14% more resale value after five years than those without any cover at all. This makes sense when we think about aircraft grade aluminum's ability to resist rust and wear. Most owners find these covers still look good and work properly even after driving past the 100,000 mile mark, which is something buyers always check during test drives. Car dealers especially appreciate when accessories are left in their original condition, matching what came from the factory. These small details can make a big difference when it comes time to sell.

Easy Installation and Compatibility Across Truck Models

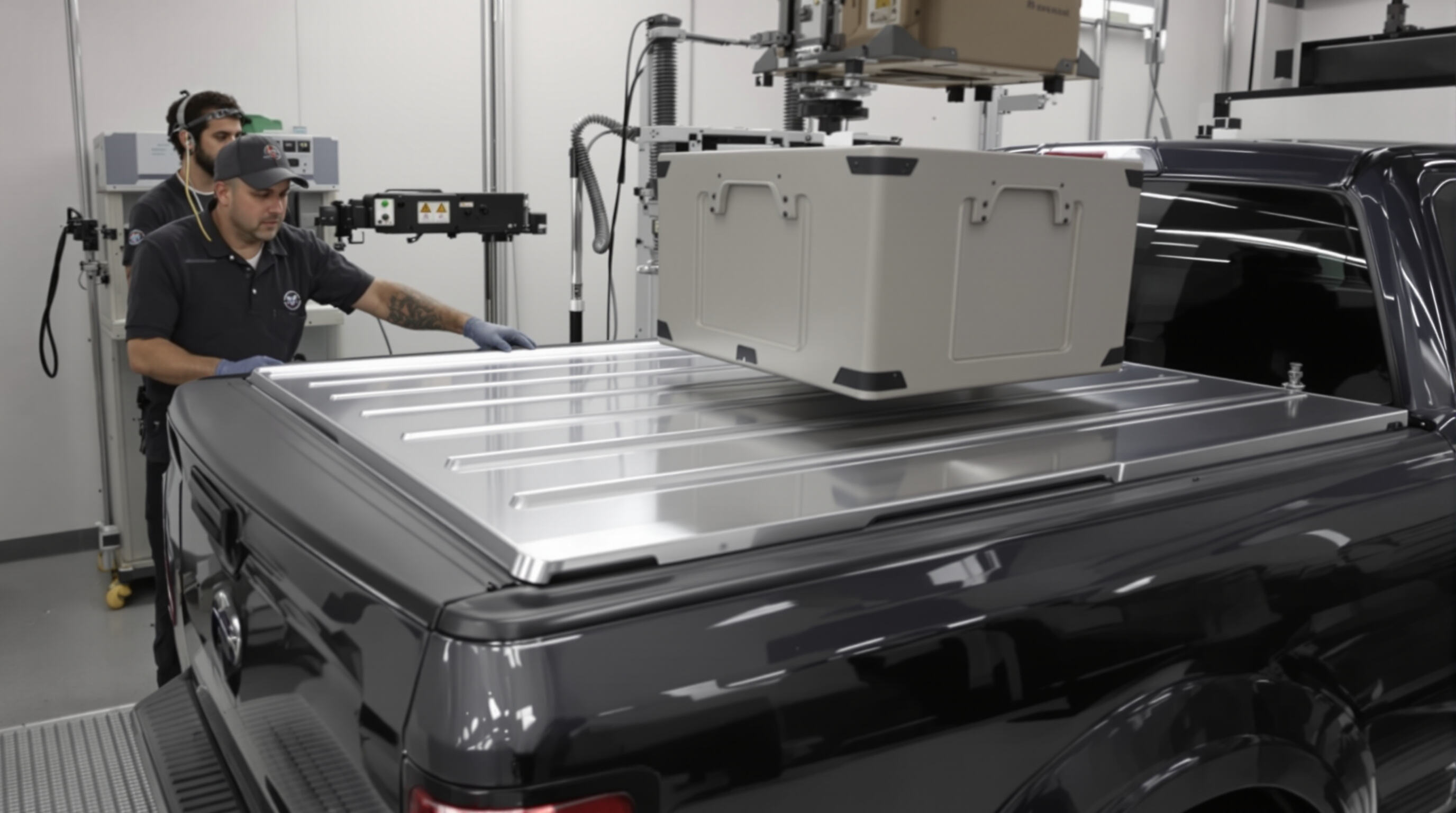

Tool-free clamp and rail systems for quick, secure installation

Aluminum tonneau covers these days have made installation much simpler thanks to their clamp based design that doesn't need any drilling or permanent changes to the truck bed. Most folks can get these pre assembled rail systems installed in about 20 minutes max with just some basic hand tools, which is way different from those fiberglass covers that always seem to need someone with special skills to fit them properly. The reinforced aluminum frames stay aligned even when going over rough roads and trails, so there's less rattling around inside. This matters a lot when transporting delicate items on backcountry adventures where every bump could damage something important.

Universal fit and adaptability for various bed sizes and brands

Most top brands design their aluminum covers to fit around 98 percent of standard full size pickup beds ranging from five to eight feet long, leaving less than twenty five millimeters gap between cover and bed. These work well even on trucks with those rough textured spray liner coatings or when someone has installed an after market toolbox. Soft covers that claim to fit everything tend to fall short, but these aluminum ones have those adjustable side rails plus special seals at the tailgate area that adapt automatically to different makes like Ford, Chevy, RAM trucks and Toyotas while still keeping water out effectively. The fact that they work across multiple brands makes them really useful upgrades for both business fleets and individual owners too. According to recent JD Power research from last year, almost nine out of ten owners are happy with how these covers handle different truck models.

FAQ

What are the benefits of using an aluminum tonneau cover?

Aluminum tonneau covers offer unmatched durability, lightweight strength, superior security, and enhanced fuel efficiency. They also improve aesthetic appeal and increase resale value.

How does an aluminum tonneau cover improve fuel efficiency?

By reducing vehicle weight and aerodynamic drag, aluminum tonneau covers help the engine work less, leading to improved fuel efficiency.

Are these covers compatible with different truck models?

Yes, most aluminum tonneau covers are designed to fit a wide range of truck models and bed sizes, providing a universal fit for optimal compatibility.

Can aluminum tonneau covers withstand extreme weather conditions?

Yes, aluminum tonneau covers are resistant to cracking, warping, and harsh weather conditions, maintaining structural integrity across various environments.