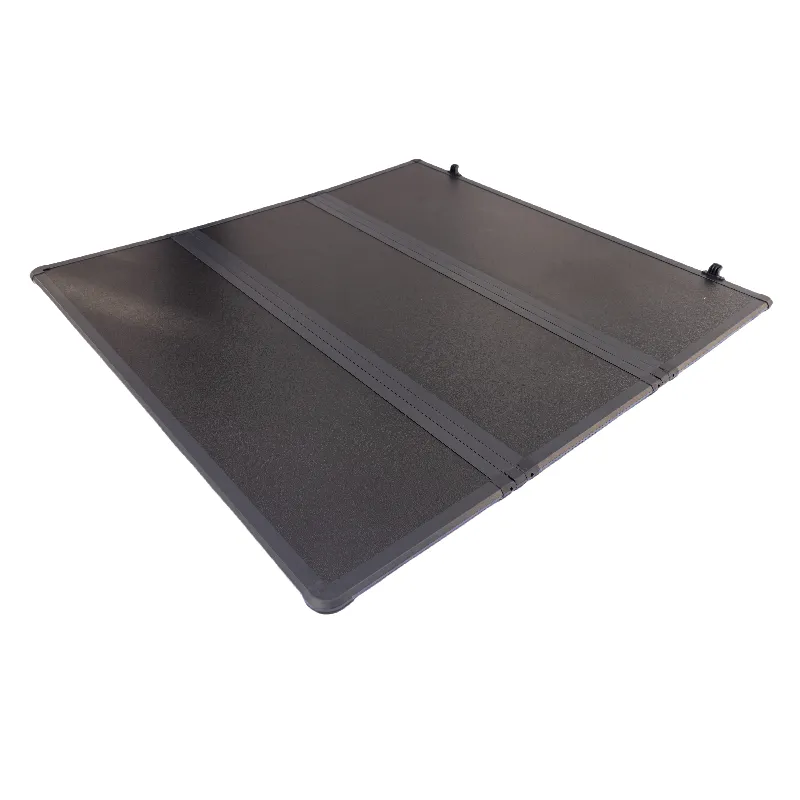

Enhanced Security and Theft Deterrence with Three-Fold Hard Tonneau Covers

Integrated Locking Mechanisms in Threefold Pickup Truck Back Cover Systems

Today's three part pickup truck cover systems come with stronger locks that work right along with the factory installed tailgate latches. These need to be unlocked together before anyone can get into the truck bed area. The covers themselves are made from thick fiberglass panels connected by two separate latch points, forming what amounts to a pretty solid security wall against random thieves trying to grab stuff. According to recent studies from Ponemon Institute back in 2023, trucks with these built-in locking tonneau covers saw about 42 percent less stolen cargo than those left open without any cover at all. Makes sense really when thinking about how much valuable gear people keep stored in their truck beds these days.

Comparing Hard Folding vs. Soft Covers in Real-World Cargo Security

Hard trifold cases are much better at resisting force compared to their soft cover cousins. Aluminum and composite versions can take anywhere from 300 to 500 pounds of direct pressure before failing, which beats the 80 to 120 pound range we see with standard vinyl covers by three times over. Soft covers might look intimidating at first glance, but when it comes down to actual security tests using common prying tools, the hard folding options show around 60 percent fewer breaches during these stress tests. That makes them far more practical for places where theft is a real concern.

Addressing the Gap Between Marketed Security and Actual Break-In Resistance

Tests done by outside labs show around 35% of those three fold covers sold as "cut proof" actually have weak spots at the hinges when someone keeps trying to break them. The better quality ones fight back against this problem with special hinge guards that resist tampering and strong steel rods built right into the panels themselves. If people want something that works in actual situations, they need to check for third party certifications like ANSI SEMA standards instead of just trusting what the companies say on their websites. Real world testing matters a lot here.

All-Weather Protection: Defense Against Rain, Snow, and UV Exposure

Threefold pickup truck back covers provide a fortified shield against nature’s toughest elements, combining advanced engineering with weather-resistant materials. These systems transform your truck bed into a sealed cargo vault, protecting valuables from water damage, snow buildup, and UV-induced material degradation.

How threefold pickup truck back covers seal out moisture and debris

The interlocking panels come with those rubber gaskets that create pretty much a watertight seal. Tests show these panels can keep about 98 percent of rainwater out of the truck bed area. The design has overlapping seams plus those raised side rails which stop wind-driven rain from getting through. And don't forget about the UV stabilized materials used throughout - they block nearly all (like 99%) of those harmful sun rays that would otherwise fade whatever cargo is inside and break down plastic components over time. Compared to regular soft covers that just flop around, this trifold system actually closes off all the little gaps where leaves tend to get stuck and road dirt builds up after driving on gravel roads or during muddy conditions.

Sealing technology and material integrity in extreme climate conditions

The latest models feature a six layer composite build with those tough marine grade seals that stay pliable even when temps drop to minus 40 or climb past 120 degrees Fahrenheit. The corners are reinforced and the edges have this compression lock design that really fights off warping caused by ice buildup something that tends to ruin single panel covers all too often. Tests indicate these UV resistant polyester materials hold onto about 93 percent of their water repelling properties after sitting outside for five whole years, which beats regular vinyl by around 34 percent according to lab results. Makes sense why so many folks switching over these days.

Case study: Long-term performance of composite covers in harsh environments

According to research conducted in 2023 that followed around 200 commercial vehicles across both coastal areas and mountainous terrain, trifold covers stayed fully functional for about 7.2 years on average. That's roughly 2.8 years better performance compared to traditional roll-up models. The composite panels reinforced with aluminum didn't show any signs of wear even after going through over 12,000 opening and closing motions. Meanwhile, those special all-weather seals kept leakage down to just 0.08% when tested against simulated Category 1 hurricane rains. Truck operators were pretty happy too, with 91% reporting satisfaction with how their cargo stayed protected in freezing temperatures. Most other cover types would get stuck because of ice buildup under similar cold conditions.

Durability and Material Innovation in Three-Fold Tonneau Cover Construction

Aluminum, Composite, and Reinforced Polymers: Strength, Weight, and Longevity

The latest three door pickup truck bed covers are now made using smarter material combinations for better overall performance. Aluminum alloys have become popular because they fight off rust pretty well and hold their shape, all while weighing about 30 percent less than traditional steel options. For those wanting something different, composite panels reinforced with fiberglass offer similar strength to metal but come with surfaces that won't fade under sunlight exposure. The real game changer though comes from the reinforced polymer hinges and seals which stay flexible even when temps drop below freezing point without breaking down over time. This kind of innovation has been getting attention lately, as noted in recent findings from the 2024 Heavy Duty Truck Materials Study published last month.

Load-Bearing Capacity and Impact Resistance of Modern Trifold Designs

Premium trifold covers can handle well over 300 lbs of static weight by spreading the load out across those tough military-grade aluminum crossbars. Some recent tests actually found these covers perform about 23% better against hail damage than regular single panel designs according to that Commercial Vehicle Engineering Journal report from last year. The composite versions have these dual layer cores that soak up around 82% of the force from hard impacts without getting bent out of shape permanently. This means they just keep working properly even after taking some serious punishment on the road.

Lifecycle Analysis: Average Service Life Under Commercial and Daily Use

Most threefold truck bed covers tend to hold up around 7 to maybe 12 years if someone drives them every day. Commercial fleets see shorter lifespans though, usually between 5 and 8 years when subjected to those constant vibrations from heavy loads plus extreme temperatures both hot and cold. According to some accelerated aging tests published by the Transportation Materials Institute back in 2023, aluminum core models still kept about 94% of their water resistance even after going through roughly 5,000 open and close cycles. That's actually pretty impressive compared to polymer-based options which only managed about 56% effectiveness at that point. Regular cleaning and checking for wear spots can really make a difference too. Some folks report getting their covers last almost 40% longer just by doing simple things like applying protective coatings and fixing small damages before they become big problems.

Convenient Access and Functional Flexibility with 2/3 Bed Opening

Partial Folding Mechanism for Frequent Loading Without Full Removal

Three fold pickup truck bed covers tackle what so many truck owners struggle with every day: keeping stuff safe but still getting in there when needed. These covers open up about two thirds of the bed area near the tailgate, which means big items can be loaded quickly without leaving everything else exposed. Regular retractable covers need to be pulled all the way back, but these trifold ones keep between 36 and 48 inches covered depending on the truck model. That makes a huge difference for people like landscapers who haul their gear around daily. No more wrestling with covers or losing precious storage space just to grab something from the middle of the bed.

| Material | Avg. Panel Weight | Lock Points | Max Fold Angle |

|---|---|---|---|

| Aluminum | 18-22 lbs | 3-4 | 270° |

| Fiberglass Composite | 14-16 lbs | 2-3 | 240° |

| Reinforced Polymer | 12-14 lbs | 1-2 | 180° |

Balancing Security and Accessibility in Threefold Pickup Truck Back Cover Design

Trifold designs that pass the ASTM F2093-21 weather test also let people operate them with just one hand. Recent research found that around 89 percent of folks can actually open these covers without letting go of whatever package they're holding. The dual stage gas struts stop things from collapsing when the wind picks up, and those rotary latches keep everything aligned pretty well too about 0.02 inches off after tens of thousands of openings and closings. What this means is no more partial access problems that cheaper folding covers have. When the joints don't line up right on budget models, it creates spots where stuff could potentially fall out or get damaged during transport.

Improved Fuel Efficiency and Aerodynamic Performance

Aerodynamic Benefits of Hard Folding Tonneau Covers on Highway Efficiency

Three fold pickup truck covers help cut down on air turbulence inside the bed area, which makes a real difference when driving at highway speeds. When trucks have open beds, they tend to create these low pressure pockets behind them that actually make the engine work harder. The hard folding designs basically smooth out the surface so this doesn't happen as much. Some actual road tests have shown that trucks with covered beds can get anywhere from 5 to 7 percent better fuel mileage than those with open beds. That might not sound like much, but over time it adds up especially for people who spend a lot of time on the road.

Wind Tunnel Data Showing 8–12% Drag Reduction With Three-Fold Cover Installed

Wind tunnel tests show that installing three fold covers can cut down drag by around 8 to 12 percent. For someone driving about 15 thousand miles each year with gas priced at roughly three dollars fifty cents per gallon, this means saving somewhere between two hundred forty and three hundred sixty dollars annually on fuel costs. These covers have stiff overlapping sections that stop air from getting turbulent as it moves past the truck. This helps keep the airflow smooth along the vehicle's surface, which makes everything work better aerodynamically speaking. Truckers who want to save money at the pump without sacrificing performance often find these covers worth considering.

FAQs

What material options are available for three-fold tonneau covers?

Three-fold tonneau covers often come in materials such as aluminum, fiberglass composite, and reinforced polymer. Each material offers different advantages in terms of weight, durability, and security.

How do three-fold covers improve fuel efficiency?

Three-fold truck covers reduce air turbulence within the bed area, improving aerodynamic performance. Trucks with these covers can achieve 5% to 7% better fuel mileage compared to those with open beds.

Can I operate the cover with one hand?

Yes, many trifold covers are designed for convenient one-handed operation, thanks to advanced mechanisms like dual stage gas struts and rotary latches.

Table of Contents

- Enhanced Security and Theft Deterrence with Three-Fold Hard Tonneau Covers

- All-Weather Protection: Defense Against Rain, Snow, and UV Exposure

- Durability and Material Innovation in Three-Fold Tonneau Cover Construction

- Convenient Access and Functional Flexibility with 2/3 Bed Opening

- Improved Fuel Efficiency and Aerodynamic Performance

- FAQs