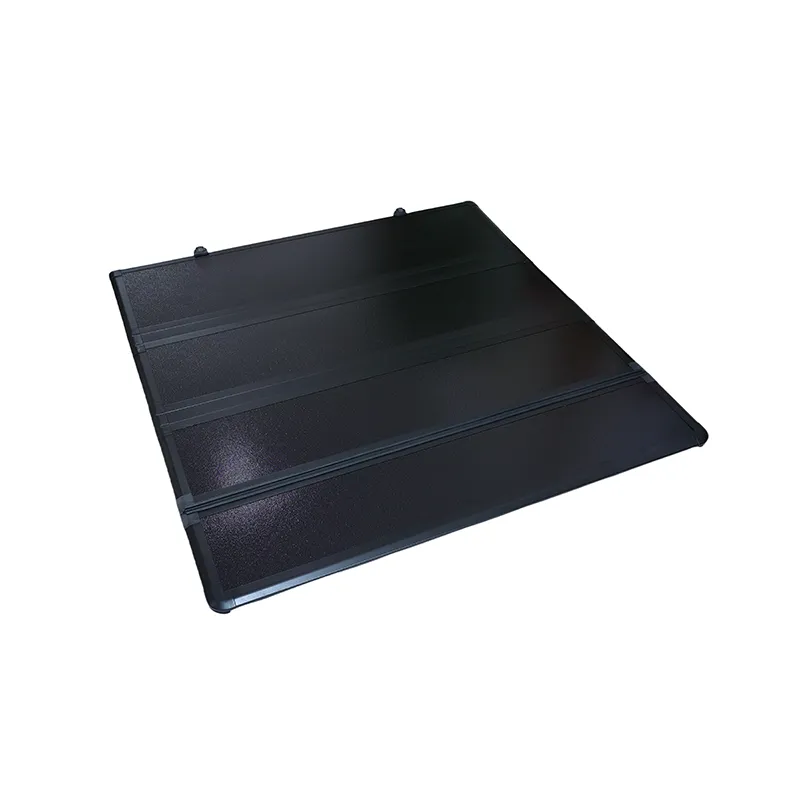

Cómo la construcción del material afecta la durabilidad exterior de las cubiertas rígidas plegables

Aluminio vs Compuesto: Resistencia, peso y resistencia al estrés ambiental

El aluminio resiste bastante bien las abolladuras y soporta altas temperaturas sin problema, lo que lo convierte en una buena opción para zonas con condiciones desérticas cálidas. Sin embargo, los materiales compuestos pesan aproximadamente un tercio menos que el aluminio y suelen resistir mejor los impactos de granizo o escombros caídos desde arriba. Ambas opciones presentan sus propios inconvenientes. El aluminio tiende a deformarse tras pasar por varias temporadas de congelación-descongelación, mientras que los compuestos comienzan a degradarse más rápidamente cuando están expuestos al sol durante largos períodos. Recientemente, los fabricantes han estado trabajando en soluciones para estos problemas. Algunas nuevas aleaciones de aluminio incorporan mayor resistencia para combatir la torsión, mientras que muchos paneles compuestos ahora incluyen recubrimientos especiales de polímero que ayudan a controlar su expansión cuando se calientan.

Recubrimientos Estabilizados contra UV y Aleaciones Resistentes a la Corrosión: Mejora de la Longevidad

Las cubiertas rígidas plegables de mejor calidad vienen con múltiples capas de protección contra daños por condiciones climáticas. Pruebas muestran que los recubrimientos estabilizados contra rayos UV pueden reducir el desvanecimiento del color en aproximadamente un 70 por ciento en comparación con materiales comunes, según investigaciones del Instituto de Materiales Automotrices del año pasado. Para personas que viven cerca de la costa, estas cubiertas incorporan piezas de aluminio marino que resisten mucho mejor la exposición al agua salada. Obsérvese también el hardware; las bisagras y cierres suelen estar recubiertos con chapado de zinc-níquel, algo que dura aproximadamente cinco veces más que lo que normalmente encontramos en componentes estándar de acero. Todas estas mejoras hacen que la cubierta dure más tiempo sin dificultar su operación, que sigue siendo posible con una sola mano tal como fue diseñada.

Resistencia Climática: Rendimiento bajo Lluvia, Nieve y Exposición Prolongada al Sol

Diseño Impermeable y Sistemas de Drenaje en Cubiertas Rígidas Plegables

Los mejores modelos del mercado utilizan en realidad múltiples capas de sellado combinadas con canales de drenaje especialmente diseñados que evitan que el agua penetre en el interior. Según pruebas realizadas en laboratorios el año pasado (el Informe de Estanqueidad Automotriz, para quien le interese), estos diseños de alta calidad pueden bloquear casi toda entrada de agua, alrededor del 99,9 % en realidad. Logran esto gracias a paneles inclinados con precisión e incorporando juntas especiales que repelen el agua, desviando la lluvia y otra humedad de donde no debería estar en las cajas de los camiones. Para una durabilidad excepcional, los fabricantes someten aluminio marino o materiales compuestos a más de 1.200 horas seguidas de condiciones de niebla salina. Este tipo de pruebas garantiza que estos camiones puedan resistir cualquier condición climática extrema sin desarrollar problemas de óxido con el tiempo.

Capacidad de carga de nieve y resistencia en ciclos de congelación-descongelación

Estas cubiertas rígidas de aluminio plegables pueden soportar una carga considerable, llegando a aguantar aproximadamente 500 libras por pie cuadrado de peso de nieve, lo que equivale más o menos al peso de seis pies de nieve fresca antes de que se produzca cualquier fallo estructural. Las juntas están reforzadas con polímeros para que no se agrieten incluso cuando las temperaturas bajan por debajo de cero grados Fahrenheit. Además, las superficies han sido tratadas con recubrimiento en polvo, lo que dificulta que el hielo se adhiera. En zonas donde los inviernos son especialmente severos, los fabricantes ofrecen modelos con sistemas de drenaje de doble etapa integrados directamente. Estos ayudan a evitar que el agua se acumule en la parte superior y reducen significativamente el daño causado por los ciclos repetidos de congelación y descongelación que acaban desgarrando los materiales con el tiempo.

Acabados protectores que previenen la degradación y decoloración por rayos UV

Los recubrimientos cerámicos nano que están estabilizados contra los daños por rayos UV en realidad reflejan alrededor del 97 por ciento de esos rayos UV A y B perjudiciales. ¿Qué significa esto? Las superficies tratadas con estos recubrimientos permanecen aproximadamente 35 grados Fahrenheit más frías que los materiales comunes no tratados, según investigaciones de la Iniciativa de Durabilidad de Materiales al Aire Libre realizada en 2022. La protección forma un enlace en la superficie que realmente ayuda a combatir la pérdida de color con el tiempo. Después de solo cinco años, la mayoría de las superficies aún se ven bastante bien, conservando alrededor del 90 % de su brillo original. También hay menos grietas a nivel microscópico, reduciendo este problema en aproximadamente un 82 %. Además, evita que los metales se oxiden o corroan, lo cual es una gran ventaja para la durabilidad. En lugares donde los materiales están expuestos constantemente al sol, aplicar estos aerosoles bloqueadores de UV una vez al año marca una diferencia notable. Los estudios muestran que la vida útil se prolonga alrededor de un 40 % en entornos severos, como regiones desérticas o zonas costeras donde el aire salino acelera la degradación.

Durabilidad en la Vida Real: Vida Útil y Mantenimiento de las Cubiertas Rígidas Plegables para Caja de Camioneta al Aire Libre

Vida Útil Esperada según el Clima y la Frecuencia de Uso

La mayoría de las cubiertas rígidas plegables deberían durar aproximadamente entre 8 y 12 años si se mantienen en condiciones promedio, pero esto varía bastante dependiendo del lugar de instalación. Las zonas costeras son particularmente agresivas con estas cubiertas debido a la sal en el aire, que desgasta las bisagras y hace que los sellos comiencen a fallar más rápido. Estamos hablando de una reducción de la vida útil de alrededor del 30 al 40 %. En el norte, el clima frío también causa problemas, con paneles que se deforman con el tiempo y mecanismos que se atascan cuando se congelan. El calor del desierto tampoco es mucho mejor, ya que la radiación UV desvanece los recubrimientos y hace que los sellos de goma se vuelvan frágiles tras algunas temporadas. Y no olvidemos que el uso diario regular desgastará las piezas más rápido que en alguien que solo abre su cubierta de vez en cuando. Espere quizás 2 o 3 años menos de servicio si la cubierta está en constante uso.

| Tipo de clima | Reducción Promedio de la Vida Útil | Puntos comunes de falla |

|---|---|---|

| Costero/Húmedo | 35% | Bisagras corroídas, sellos con moho |

| Norte/Zona de Nieve | 25% | Paneles deformados, pestillos congelados |

| Desierto/Alta UV | 20% | Recubrimientos desvanecidos, sellos frágiles |

Prácticas Esenciales de Mantenimiento para Preservar la Función y la Apariencia

Tres prácticas clave previenen el 85 % de los fallos prematuros:

- Inspecciones mensuales de los sellos : Verifique la presencia de grietas por envejecimiento o huecos en las juntas de goma, especialmente antes de las temporadas de lluvia

- Lubricación Estacional de las Bisagras : Aplique lubricantes a base de silicona (no de petróleo) en los puntos de articulación para prevenir la corrosión

- Aplicación Semestral de Protector UV : Restaure la resistencia al agua en las juntas de vinilo y evite el amarilleo del policarbonato

Evite lavar con chorro a presión cerca de las juntas, ya que chorros superiores a 60 PSI pueden forzar residuos dentro de los canales de drenaje. En su lugar, limpie con jabón automotriz de pH neutro y una gamuza de microfibra para preservar los acabados protectores.

Cómo Elegir la Lona Dura Plegable Correcta para el Clima Regional

Seleccionar una lona dura plegable adecuada para su clima requiere combinar materiales con los factores ambientales agresivos. Las regiones desérticas, costeras y del norte exigen soluciones de ingeniería específicas para un rendimiento óptimo.

Asociación de Materiales de Lona con Condiciones Climáticas Extremas (Climas Desérticos, Costeros y del Norte)

el aluminio de la serie 6000 es ideal para climas desérticos, ya que ofrece propiedades reflectantes de rayos UV y disipación del calor. Las zonas costeras se benefician de componentes de acero recubierto con polvo y fijaciones fosfatadas, que reducen la corrosión por agua salada hasta en un 80 %. En climas del norte, los paneles de polímero reforzado con fibra mantienen su integridad entre -40 °F y 140 °F, incluso bajo cargas pesadas de nieve.

| Tipo de clima | Material Óptimo | Característica Crítica |

|---|---|---|

| Desierto | aluminio de la Serie 6000 | Reflectante de rayos UV, disipación del calor |

| Coastal | Acero recubierto en polvo | Resistencia a la corrosión por agua salada |

| Del norte | Polímero reforzado con fibra | tolerancia térmica de -40 °F a 140 °F |

Equilibrar durabilidad y facilidad de uso sin comprometer el rendimiento

Las cubiertas rígidas plegables premium integran lamas de aluminio de 3 mm de espesor con puntos de giro de baja fricción, lo que permite una operación suave con una sola mano. Sellos de goma de doble etapa en las uniones de los paneles bloquean la humedad permitiendo al mismo tiempo un movimiento flexible, esencial para conductores en regiones húmedas o nevadas que necesitan acceso frecuente al compartimento de carga.

Sección de Preguntas Frecuentes

1. ¿Qué materiales se utilizan comúnmente para las cubiertas rígidas plegables?

Las cubiertas rígidas plegables suelen utilizar materiales como aluminio y materiales compuestos, cada uno con sus beneficios y desventajas en términos de resistencia, peso y resistencia al estrés ambiental.

2. ¿Cómo afectan los recubrimientos estabilizados contra UV a la durabilidad de las cubiertas para toneladas?

Los recubrimientos estabilizados contra UV reducen significativamente el desvanecimiento del color debido a la exposición solar, aumentando la vida útil de las cubiertas aproximadamente un 70 % en comparación con materiales comunes.

3. ¿Qué prácticas de mantenimiento ayudan a prolongar la vida útil de las cubiertas para toneladas?

Las inspecciones mensuales de sellos, la lubricación estacional de bisagras y la aplicación semestral de protectores contra UV son prácticas esenciales para evitar fallas prematuras y mantener la funcionalidad y apariencia.

Tabla de Contenido

- Cómo la construcción del material afecta la durabilidad exterior de las cubiertas rígidas plegables

- Resistencia Climática: Rendimiento bajo Lluvia, Nieve y Exposición Prolongada al Sol

- Durabilidad en la Vida Real: Vida Útil y Mantenimiento de las Cubiertas Rígidas Plegables para Caja de Camioneta al Aire Libre