Material Durability and Weather Resistance for Global Climates

Thermal Stability, UV Resistance, and Corrosion Protection Across Extreme Environments

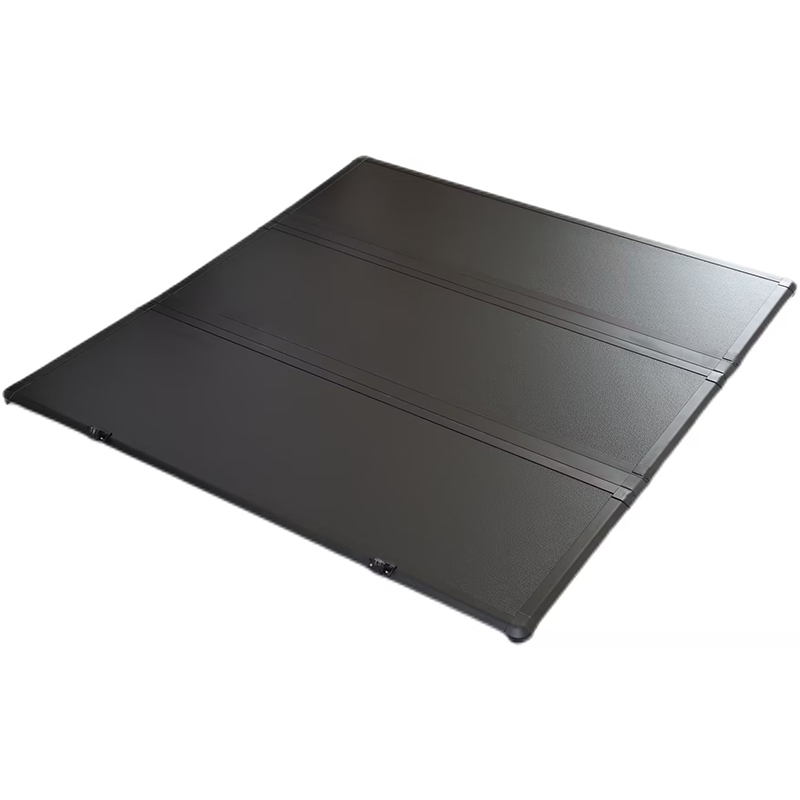

High quality truck bed covers stay strong even when temperatures swing wildly between extremes like -40 degrees Fahrenheit in Arctic conditions and scorching 200 degrees during Middle Eastern summers without bending, breaking, or peeling apart. The covers contain special UV inhibitors mixed into their polymer base that stop damage from sunlight, keeping them tough and looking good after spending around 10,000 hours under direct sun which would be like leaving them outside for five straight years near the equator. For trucks operating near coastlines or in manufacturing areas where salt air is a problem, manufacturers use marine grade aluminum and steel frames coated with protective powders to fight off rust. Tests show these specialized materials lose only about 2% of their surface quality compared to regular options after sitting out for five years in both humid tropics and dry desert climates. This attention to materials means cargo stays safe whether driving through monsoons in Southeast Asia, crossing dusty deserts, or navigating the wet and warm conditions found throughout many parts of Southeast Asia.

Sustainable Material Innovation: Recycled TPU and Bio-Composite Truck Bed Covers

Many top manufacturers are starting to use recycled Thermoplastic Polyurethane (TPU) that comes from factory waste instead of sending it to landfills. This approach cuts down on waste going into landfills by around 70%, all while keeping the material's durability against wear, its flexibility, and that important IP67 water protection rating. Alongside this trend, there are also these bio-composite panels made from fast growing plant fibers mixed with resins derived from biological sources. These new materials slash carbon emissions during manufacturing by about 40%. Tests have shown they work just as well functionally speaking too. The panels can handle over 1,500 loading cycles without bending out of shape permanently, and they hit the same level of impact resistance as regular composite materials made from new stuff. For companies trying to meet their environmental commitments and follow regulations such as ISO 14040 standards, these developments represent a big step forward toward building products that fit within a circular economy model.

Enhanced Security and Cargo Protection for International Logistics

Truck bed covers that are built tough offer real protection against cargo theft, which is becoming a bigger problem worldwide. Especially when goods just sit there at borders, ports, or out in the middle of nowhere waiting for something to happen. The best ones come with locks that work well, strong seals around the edges, and hardware that makes it hard for thieves to mess with them. People trying to steal stuff usually give up when they run into these kinds of obstacles. But good covers do more than keep things safe from bad guys. They also stop water, dirt, and all sorts of junk from getting inside the truck bed. This matters a lot for things like electronic equipment, medicine, and food products that need special handling while moving between different transport modes. When companies invest in quality covers, they end up saving money on insurance claims related to stolen goods, avoid delays caused by spoiled merchandise, and generally build better trust with their international trading partners over time.

Global Regulatory Compliance and Structural Performance

Meeting DOT, ECE R116, and ASEAN-Specific Strength and Visibility Standards

Meeting local safety and performance standards is pretty much a must if companies want their products on store shelves. Take North America for instance, where the DOT FMVSS 226 regulation demands that truck bed covers can handle impact forces 1.5 times what the vehicle is rated for, all while keeping rear visibility intact and maintaining structural integrity. On the other side of the pond, European rules under ECE R116 set a minimum of 70% light transmission through those see-through rear panels, so drivers can still see clearly at night. Many ASEAN countries are starting to adopt similar requirements as freight traffic grows and road safety becomes a bigger concern. When it comes to proving compliance, top manufacturers run through standard accelerated testing procedures. These include exposing materials to UV light for over 1,000 hours, subjecting them to salt spray simulations lasting 1,500 hours, and cycling through high humidity conditions above 80% RH. Getting these tests aligned across different regions saves manufacturers around 40% in time to market and prevents expensive rework when shipping goods across borders.

Balancing Structural Integrity and Lightweight Design for EV-Compatible Truck Bed Covers

Electric pickup trucks are becoming increasingly popular, and as they do, manufacturers are focusing heavily on reducing vehicle weight. For instance, cutting down just 10 kilograms can actually boost the actual driving range by around 1.5 kilometers in real conditions. Carbon fiber reinforced polymers offer incredible strength ratings over 1,200 MPa but come in at roughly 60% lighter than traditional steel components. When it comes to aerodynamics, designers have been refining shapes using complex computer simulations that bring drag coefficients below 0.35 Cd, which helps counteract the negative effects of larger front areas on overall range. Safety remains a top concern too these materials need to withstand impacts greater than 200 Joules and maintain stability against vibrations at frequencies around 25 Hz when driving off road. New industry standards like ISO 20762 now mandate proper EMI shielding so signals between batteries and control systems stay intact without interference, making sure all these innovations work smoothly together in future electric vehicle designs.

Design Adaptability and Regional Customization for Diverse Pickup Use Cases

Modular Truck Bed Cover Configurations for Off-Road, Towing, and Urban Payload Efficiency

Truck bed covers need to handle all sorts of real world conditions, whether it's muddy farm roads or packed city streets where deliveries happen fast. Farmers and people who drive off road really appreciate tough modular designs that come with higher ground clearance, strong hinges that won't break, and those plastic skid plates that take the hit when things get rough. City delivery trucks want something different though. They look for covers that stay low to the ground so they can load up more stuff, plus ones that open quickly so just one person can manage them even in tight spaces at loading areas. Materials change depending on where you are too. Places with lots of sun need covers made from UV resistant plastics, while cold climates in places like Scandinavia and Canada require special composites that stay flexible below freezing temperatures. The best systems let parts swap out easily. Take away side panels when moving big construction items, add stronger attachment points for heavy towing jobs, or adjust the shape to cut wind resistance on highways. These adaptable covers turn a simple truck bed into either a secure container for expensive gear or an open workspace for carrying wood and tools, all within just a few minutes. That kind of flexibility makes sense for both businesses running commercial fleets and individuals who love weekend adventures.

FAQ

What materials are used in truck bed covers for extreme weather conditions?

High-quality truck bed covers use materials like marine grade aluminum, steel frames with protective powders, and UV-resistant polymers to withstand extreme temperatures and weather conditions without degrading.

How do recycled TPU and bio-composite panels contribute to sustainability?

They reduce landfill waste by 70% and cut carbon emissions by 40% during manufacturing, while maintaining functional durability and impact resistance comparable to traditional materials.

What are the security features of quality truck bed covers?

Quality truck bed covers come with durable locks, edge seals, and robust hardware to prevent theft and protect cargo from environmental elements.

Why is regulatory compliance important for truck bed covers?

Compliance ensures safety and performance standards are met, allowing products to be sold internationally without modifications, thus minimizing time-to-market and rework costs.

How do EV-compatible truck bed covers differ from traditional ones?

They focus on lightweight design using carbon fiber reinforced polymers and offer aerodynamics enhancements to improve electric vehicle driving range, while maintaining structural integrity and safety features.

Table of Contents

- Material Durability and Weather Resistance for Global Climates

- Enhanced Security and Cargo Protection for International Logistics

- Global Regulatory Compliance and Structural Performance

- Design Adaptability and Regional Customization for Diverse Pickup Use Cases

-

FAQ

- What materials are used in truck bed covers for extreme weather conditions?

- How do recycled TPU and bio-composite panels contribute to sustainability?

- What are the security features of quality truck bed covers?

- Why is regulatory compliance important for truck bed covers?

- How do EV-compatible truck bed covers differ from traditional ones?