Fleet-Critical Performance Criteria for Hard Folding Tonneau Covers

Why Retail-Grade Selection Fails Commercial Fleets

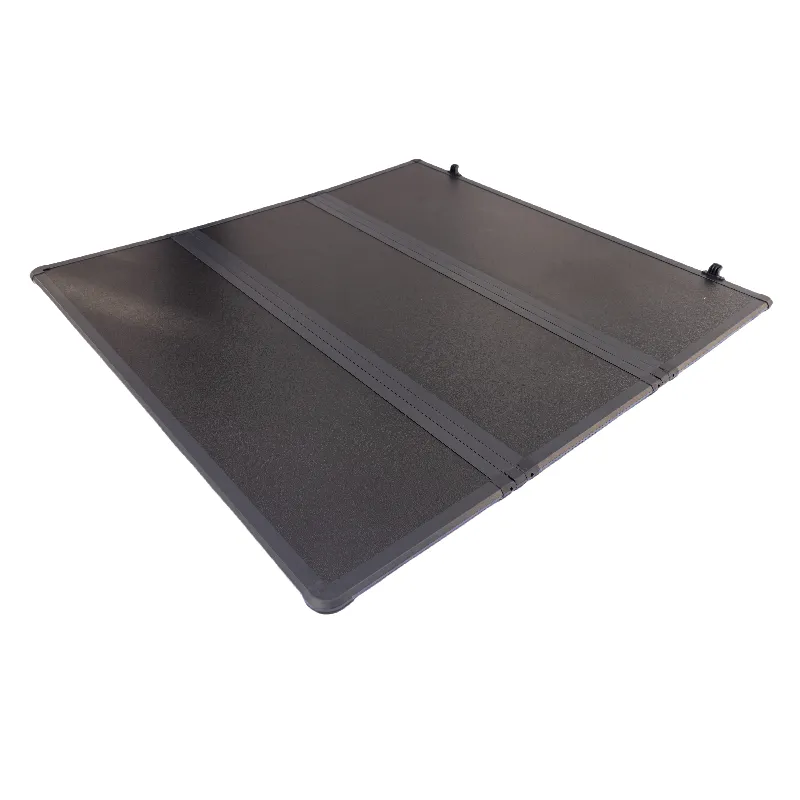

Hard folding tonneau covers sold in retail stores often focus too much on looking good rather than lasting long, which creates problems for truck fleets. While regular consumers might only drive their trucks now and then, commercial vehicles face something else entirely. They deal with constant loading and unloading, brutal heat waves in summer, freezing cold in winter, plus all sorts of dirt and rocks kicked up from roads. The cheaper retail panels usually don't have those strong reinforced hinges we need. Most break down within 12 to 18 months when put through real fleet work, whereas commercial grade ones can last over five years without issues. Security is another big concern. According to Transport Security Council data from last year, nearly two thirds of theft cases among fleets happened because the standard covers had weak or broken latches. All these breakdowns mean more time spent fixing things and higher expenses replacing parts. For anyone running a serious logistics operation, going with retail quality covers just isn't worth the risk.

Aligning Hard Folding Tonneau Cover Specs with Uptime, Security, and Maintenance KPIs

Getting the most out of a fleet starts with picking covers that actually improve how things run, not just look good or cost less. Look for those seals and locking systems that have passed ASTM D4169 testing first. These tested components cut down on cargo damage from bad weather by almost 90%, way better than generic options that haven't gone through proper validation. When thinking about keeping vehicles running smoothly, go for panels where drivers can open them in under two minutes flat. Also check for materials that won't rust easily since this saves time spent fixing problems later. Security-wise, nothing beats dual stage locks combined with hardware that thieves can't mess with. Fleet tests show these setups stop attempted break-ins around 75% of the time. And don't forget about smart covers equipped with telematics capabilities. They send early warnings when hinges start wearing down or seals begin to fail, cutting unexpected repairs by roughly 40%. All these specs matter because they turn what was once just another truck accessory into something that genuinely boosts productivity across the board.

Cross-Platform Compatibility Across Mixed-Fleet Truck Configurations

Navigating OEM Bed Variants and Aftermarket Accessories

Getting hard folding tonneau covers to work properly across different trucks is a major headache for fleet managers. Truck beds just aren't made the same way from one manufacturer to another. Take Ford's F-Series for instance, which comes with bed lengths ranging anywhere from 5.5 feet all the way up to 8 feet long. Meanwhile Ram has gone in a completely different direction with their trucks featuring those fancy multifunction tailgates plus built-in tie down points throughout the bed area. Then there's the whole mess created by aftermarket gear such as ladder racks and heavy duty toolboxes that get in the way during installation. According to recent data from NTEA (2023), almost 4 out of 10 fleets run into serious fitting problems because these items clash with standard cover mounts. The bottom line? Standard mounting solutions make life much easier for companies running mixed fleets. Custom brackets tailored specifically for each truck model can really eat into budget numbers, sometimes adding nearly 30% extra cost to parts inventory. That's why universal rail systems have become so popular lately. They cut down on special modifications needed for individual vehicles and still manage to handle most factory variations along with typical accessory setups without too much hassle.

Modular Mounting vs. Vehicle-Specific Brackets: Scalability Tradeoffs

When it comes to expanding fleet operations, modular mounting systems really shine in terms of scalability. Traditional vehicle-specific brackets do provide exact fits for each model, but this approach creates headaches when scaling up. Every new truck model requires different parts numbers, specialized training sessions, and unique installation procedures that eat into productivity. The newer modular setups with their adjustable clamps and standard rail systems work on around 92% of Class 2-3 trucks according to Commercial Fleet Magazine from last year, cutting down setup time by roughly 40% per vehicle. Of course there are downsides worth noting. Those old school brackets tend to have built-in locking mechanisms right in the factory frame which adds an extra layer of security. Modular options sometimes need additional protection against weather damage in tough conditions. Still, for companies looking to grow past about 20 vehicles, most operators find that the time savings and cost reductions from going modular more than make up for these minor drawbacks.

Commercial-Grade Durability, Security, and Weather Resistance

Seal Degradation and Latch Failure: Top Drivers of Warranty Claims

About 42% of warranty claims for fleet vehicles come down to seal problems or failed latches according to recent industry reports from 2023. That's actually three times higher than what we see in regular consumer markets. The harsh realities of constant UV exposure, chemical damage from roads, and ongoing mechanical stress really wears things down much quicker than most people expect. For commercial grade covers, specs matter a lot. Look for those with reinforced EPDM seals and stainless steel latches that can handle temperatures ranging from minus 30 degrees Fahrenheit up to 160 degrees without failing. Some field testing shows something interesting too. Covers made without proper chemical resistant polymers tend to break down around 67% faster when they're regularly hit by deicing salts and diesel fumes. And when that happens? Water gets in, cargo gets ruined, and security becomes compromised pretty quickly.

ASTM D4169 Benchmarks for Hard Folding Tonneau Cover Seals and Locking Systems

ASTM D4169 is the definitive transportation simulation standard for validating commercial-grade durability. It subjects seals and locks to vibration profiles replicating 250,000 miles of real-world fleet service—revealing hidden weaknesses before deployment. Key test parameters include:

- Cycle Testing: 5,000+ open/close cycles under full load

- Thermal Shock: Instant transitions from 140°F to -40°F

- Salt Spray: 500-hour corrosion resistance validation

- Impact Resistance: 1.5m drop tests with full cargo load

Covers achieving Tier III certification reduce weather-related failures by 58% versus non-certified models. Critically, the standard’s vibration protocols identify premature seal fatigue—the root cause in 31% of field failures (2024 fleet maintenance reports).

Total Cost of Ownership for Hard Folding Tonneau Cover Fleet Deployments

Hidden Costs: Installation Labor, Model-Specific Calibration, and Panel Replacement Lead Times

Fleet managers frequently underestimate three critical TCO drivers in hard folding tonneau cover deployments:

- Installation labor varies 3–5 across models due to alignment complexity and specialized tooling

- Model-specific calibration requires 45–90 minutes per vehicle to ensure seal integrity and latch synchronization

- Panel replacement lead times average 14–28 days during failures—costing $850/day per idle truck in lost revenue

Industry benchmarks reveal a counterintuitive pattern: lower-priced covers incur 32% higher lifetime costs from hidden operational burdens. A 5-year TCO comparison illustrates the disparity:

| Cost Factor | Value-Option Cover | Commercial-Grade Cover |

|---|---|---|

| Installation Labor | $240 per vehicle | $85 per vehicle |

| Calibration Frequency | 2 annually | Triennial |

| Panel Lead Time | 28 days | 7 days |

| Downtime Costs | $24,200 per fleet | $6,800 per fleet |

Choosing based solely on purchase price ignores the compounding impact of technician wages during installation, OEM-specific calibration modules, and inventory delays for replacement panels. These hidden variables typically consume 18–24% of a fleet’s annual accessory budget.

FAQ

What are the common issues with retail-grade tonneau covers for commercial fleets?

Retail-grade tonneau covers often lack the durability and security features needed for commercial use, leading to frequent breakdowns and theft issues.

How can fleet managers improve uptime with tonneau covers?

By choosing covers with ASTM D4169-tested components, robust locking systems, and telematics for early warnings about wear and tear.

Why is cross-platform compatibility important for fleet managers?

It reduces fitting problems and costs associated with custom brackets by allowing standard mounting solutions to work across various truck models.

What factors drive the total cost of ownership for hard folding tonneau covers?

Installation labor, model-specific calibration, and panel replacement lead times are critical TCO drivers.